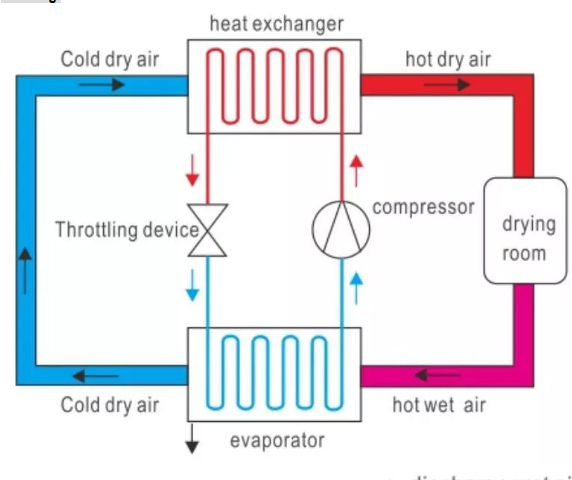

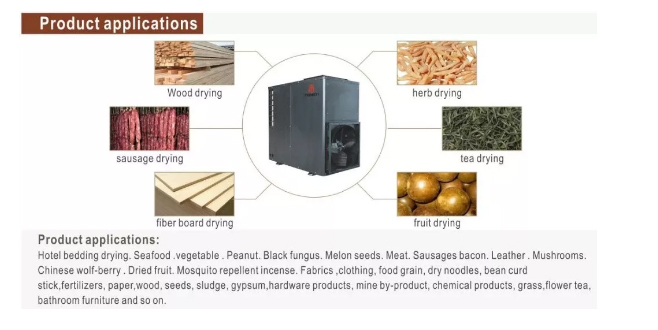

Dryer Applications

Also for Hotel bedding drying, wood, Vegetable, Peanut, Black fungus, Melon Seeds, Meat, Sausages bacon, Leather, Mushrooms, Chinese wolf-berry, Dried fruit, Mosquito, Repellent incense, Fabrics, Clothing, Foodgrain, Dry noodles, Bean curd stick, Fertilizers, Paper, Wood seed, Sludge, Gypsum, Hardware products, Mine by-product, Chemical products, Grass, Flower tea, Bathroom furniture and so on.

Capacity Range:

20KW,40KW,80KW

Key Features

High COP

Compared with traditional drying, TOGNYI heat pump dryers are200%~400% high efficiency better with heat pump and heat recovery technology.

Copeland EVI scroll compressor

World-famous scroll compressor with low energy consumption and high energy efficiency output, which effectively shortens the heating water time and double extends the useful life of the unit.

Tongyi heat pump can increase over 20% heating capacity even though works under severe weather.

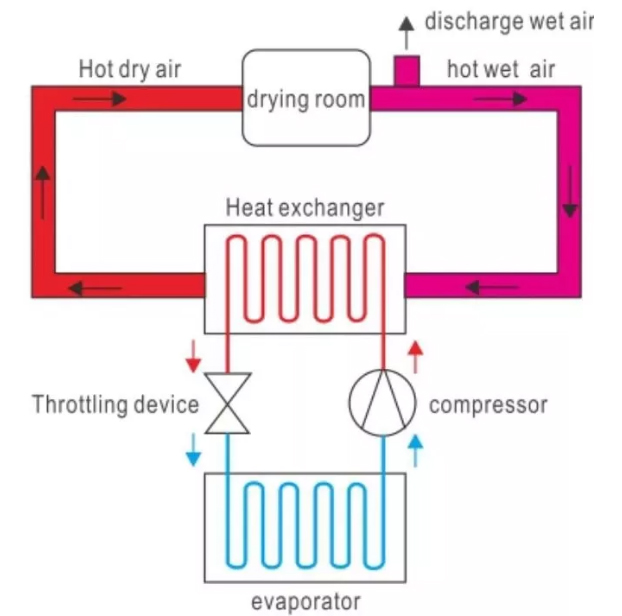

Heat exchanger

Embedded heat recovery heat exchanger increasing efficiency.

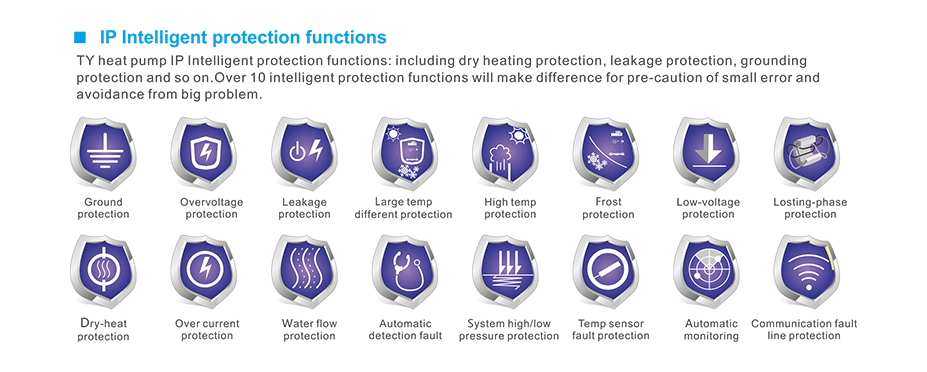

Multi-protections

The system runs safely, steadily, and reliably thanks to our full protection: high-temperature protection, compressor overload & overheat protection, power phase sequence & over/under voltage protection, etc.

EEV, precise flow control

Wide working temperature range, faster and more accurate refrigerant flow control than capillary and mechanical expansion valve. Best choice to achieve higher efficiency and energy-saving.

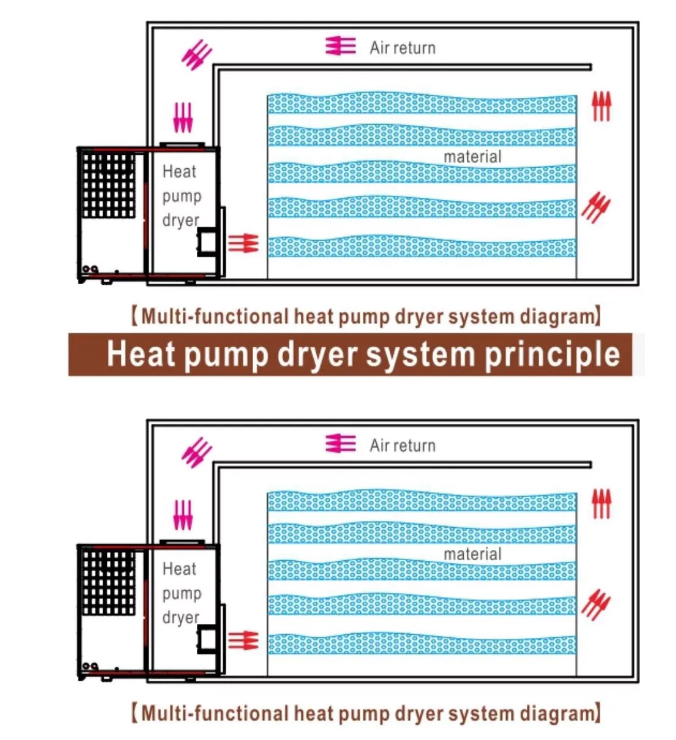

Flexible Installation

The Cuboid shape module design of the unit makes the project installation save more space.

Remote control

BMS contact point / Modbus support(with RS485) to Amazon cloud, realize remote control function optional

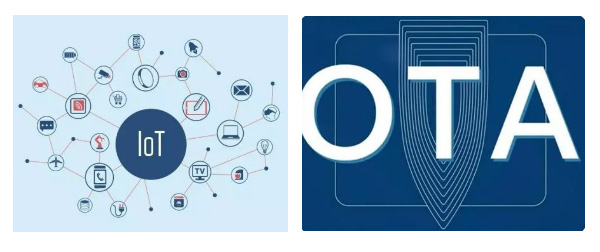

IoT

With IoT technology, we can check the heat pump status remotely. When there is fault occurs, it is easy for us to check the product information and give immediate support to our customers.

With OTA(update over air) technology, If there is any error that happens on the software, we can do the remote service by updating the software online. And when the software has a new version with the function upgraded, as long as we got your permission, we can update the software remotely.

Prototype:

Quality Control

Quality is taken into account since product design through the whole product life-cycle. With professional design procedure, simulation, and over 30 type tests, from incoming parts inspection to out-going heat pump inspection during production.

R&D

With the Research center, product design department, and product engineering team, we have technical talents with over 20+ years in heat pumps, the development is managed by PLM(Production Lifecycle Management system) with the design procedure.

Certificate